Ree’s Sleeve

11/19

Ree’s Sleeve was our deep dive into a hyper-personal Human Centered Design project for Critical Practices (NM C166). The goal with this project was to select a very specific individual and design something solely for them. To get to know this person well enough, we conducted an initial interview to introduce ourselves and a deep interview to really dive into the details. We formed a personal ethnography that contains this person’s particular habits, schedules, interests, likes, dislikes, activities, goals, passions, fears, and fantasies.

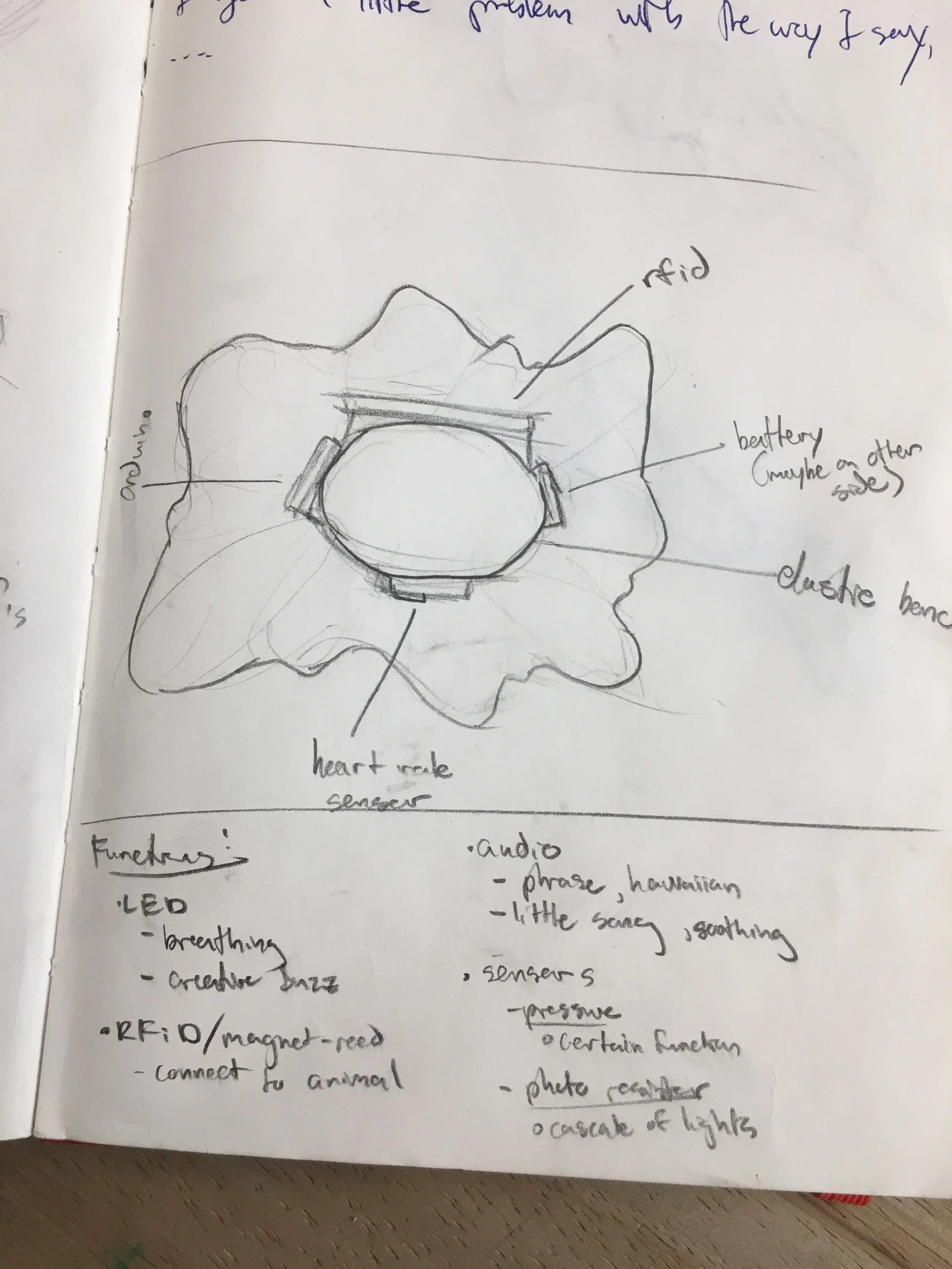

Our hyper-personal prototype was conceptualized around the needs and style of our subject, Ree Botts (the CEO of The Selfology Movement). She is an extremely warm, charismatic, and open person, who’s love of those around her is passionate and unwavering. Her life centers around healing her community, and her style is self-described as “extra.” In an effort to remind her to take some time for herself, we designed a wearable sleeve in her funky style that plays her favorite music when activated by her stuffed animal, and has LEDs that lead a breathing exercise when a conductive thread “button” is touched.

Created along with the great pleasure of Maria Pettis and Alex Ellison.

Skills utilized:

Human Centered Design

Interviewing (James Spradley principles)

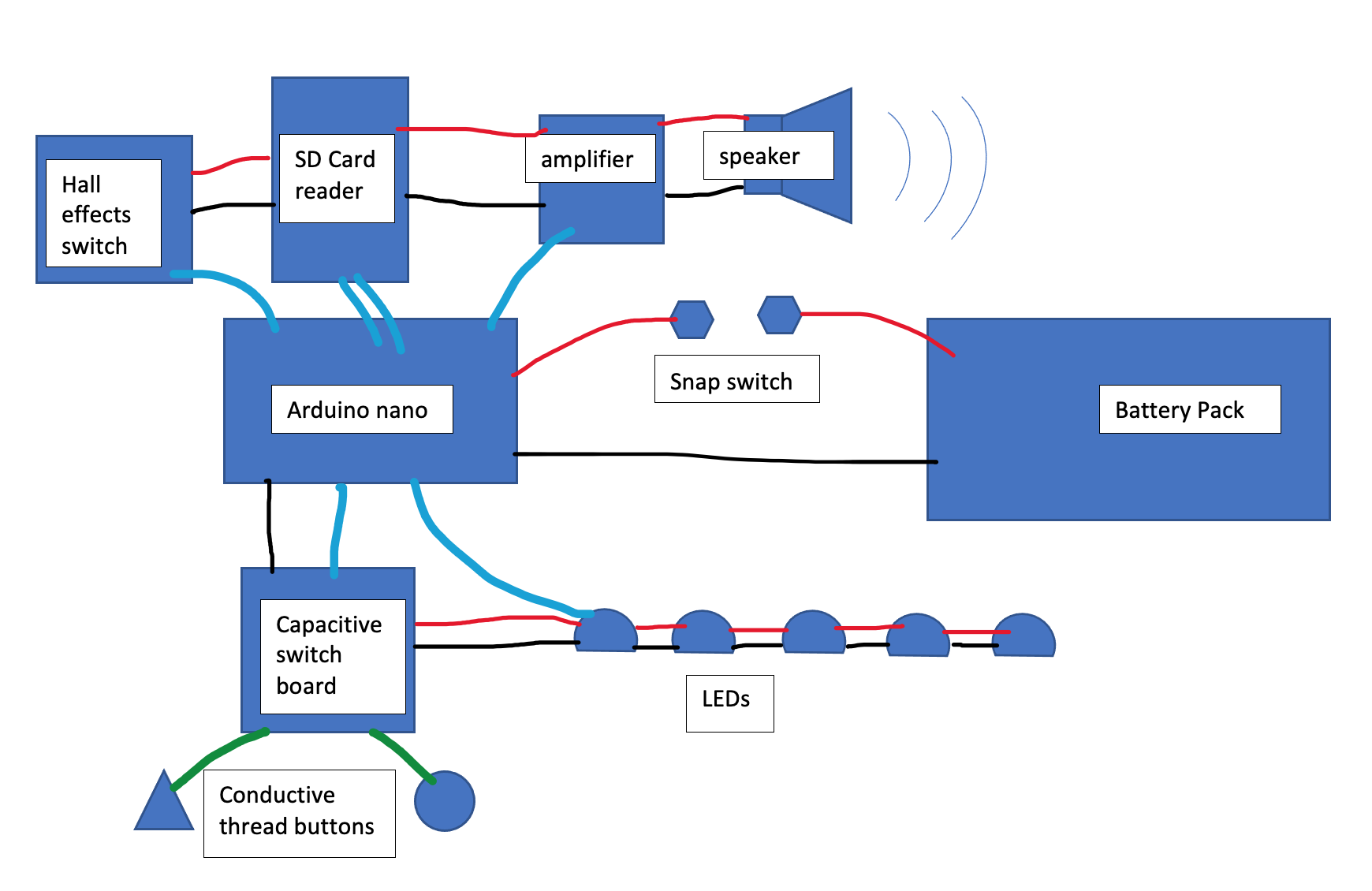

Microcontroller use and custom electronics

Programming (C++)

CAD (Fusion 360)

3D Printing

Design and Manufacturing

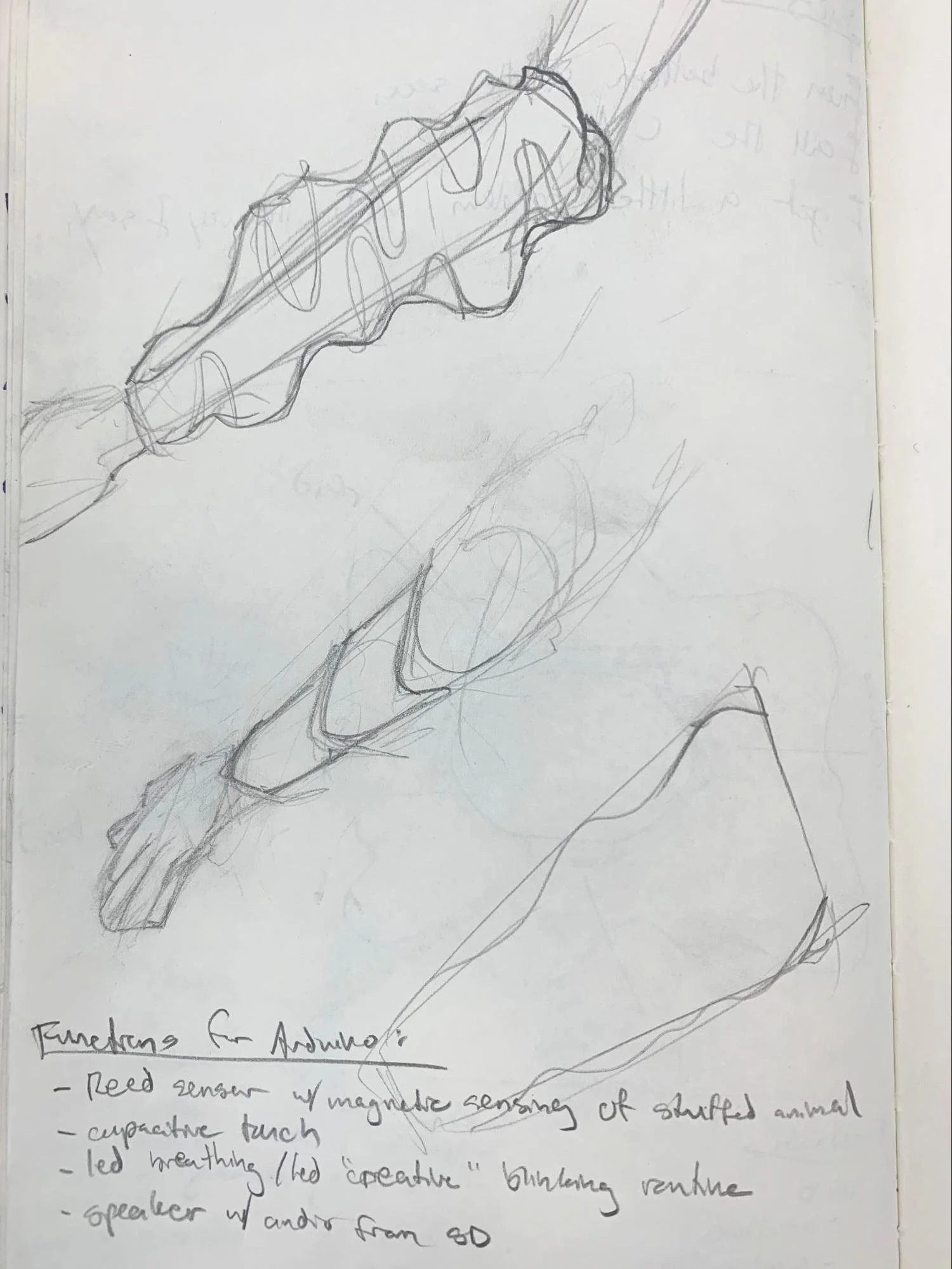

We wanted this product to fit as naturally and seamlessly into Ree’s life as possible. To do this, we revolved our ideas around a wearable which would perfectly into her existing style. We wanted to make everything a soft tangible experience so as to enhance the feeling of comfort and relaxation. Soft fabrics and conductive thread replacing buttons were used to achieve this.

We started out by sketching out ideas for the design of our wearable. Initial ideas included a pendant, earrings, or a bracelet, but we ultimately landed on a retro sleeve. We laid out the system architecture so that we knew which components would be needed and how they would interact. Once we had everything planned out, we put together the electronics and the fabric wearable, 3D printing enclosures where needed (for the microcontroller and speaker). Lots of tinkering and iterating was required to get all the electronics working reliably.